What Are Robotic Arm CNC Machines?

Robotic arm CNC machines combine CNC precision with robotic flexibility, offering multi-directional movement and high accuracy. These machines handle complex geometries, reduce manual repositioning, and improve production efficiency. Industries like aerospace and automotive use them for crafting intricate parts while addressing labor shortages and maintaining quality. Key components include servo motors, sensors, and controllers, ensuring precise operation. While they provide consistent results and reduce labor costs, challenges include high upfront costs, programming complexity, and space requirements. Choosing the right machine depends on factors like payload capacity and repeatability.

Main Components of Robotic Arm CNC Machines

Main Structural Parts

At its core, the base provides stability and serves as the foundation for the robotic arm. It also houses critical components like electrical connections, hydraulic pumps, and cooling systems, ensuring smooth operation.

The joints are what give the robotic arm its range of motion, mimicking the flexibility of a human arm. Most robotic arm CNC machines are equipped with six to seven joints, allowing for complex rotational and pivoting movements. These joints rely on precision bearings and are typically powered by servo motors for accuracy or hydraulic actuators for handling heavier loads.

Actuators play a key role by converting electrical or hydraulic energy into mechanical motion at each joint. High-end machines often feature direct-drive motors to minimize gear backlash, while hydraulic actuators are used in applications requiring the movement of heavier objects.

The end effector, attached to the wrist of the robotic arm, is where the actual machining happens. These tools - such as high-speed spindles, plasma torches, or grinding wheels - can be swapped out quickly for different tasks, thanks to automatic tool changers that streamline production.

Links connect the joints and provide structural support, enabling the arm to move seamlessly across its range of motion. These links are typically made from lightweight yet durable materials like aluminum or carbon fiber, and they house wiring, coolant lines, and tubing. Integrated cable management ensures that these elements don’t interfere with the arm’s movements.

With these structural elements in place, sensors and controllers work together to deliver precise and adaptive operation.

Sensors and Controllers

Position sensors are essential for tracking the exact location of each joint during operation. Encoders attached to servo motors provide real-time feedback for precise positioning. Many systems use absolute encoders, which retain position data even after power loss, saving time otherwise spent on recalibration.

Force and torque sensors monitor resistance during machining, helping to protect both the tool and the workpiece. These sensors can adjust feed rates in response to unexpected material resistance and are also valuable for tracking tool wear over time.

Vision systems, equipped with cameras and laser scanners, assist in locating parts and verifying dimensions during machining. Using 3D scanning, they create detailed surface maps that allow for toolpath adjustments to accommodate slight variations in parts. Some systems even incorporate thermal imaging to monitor cutting temperatures and prevent overheating.

The main controller acts as the brain of the robotic arm, processing inputs from sensors and coordinating all movements. Modern controllers use industrial PCs and real-time operating systems to translate tool positions into synchronized joint movements with incredible speed and accuracy.

Safety systems are a critical component, ensuring both operator and machine protection. Features like light curtains, emergency stops, and collision detection are standard. In collaborative environments, force-limit technology halts the robot instantly upon unexpected contact, while zone monitoring systems create virtual boundaries, slowing or stopping the robot when personnel come too close.

Communication interfaces ensure the robotic arm works seamlessly within a manufacturing environment. Ethernet-based protocols like EtherCAT enable real-time communication with other systems, such as conveyor belts or inspection stations. Additionally, cloud connectivity allows for remote monitoring and supports predictive maintenance by analyzing sensor data continuously.

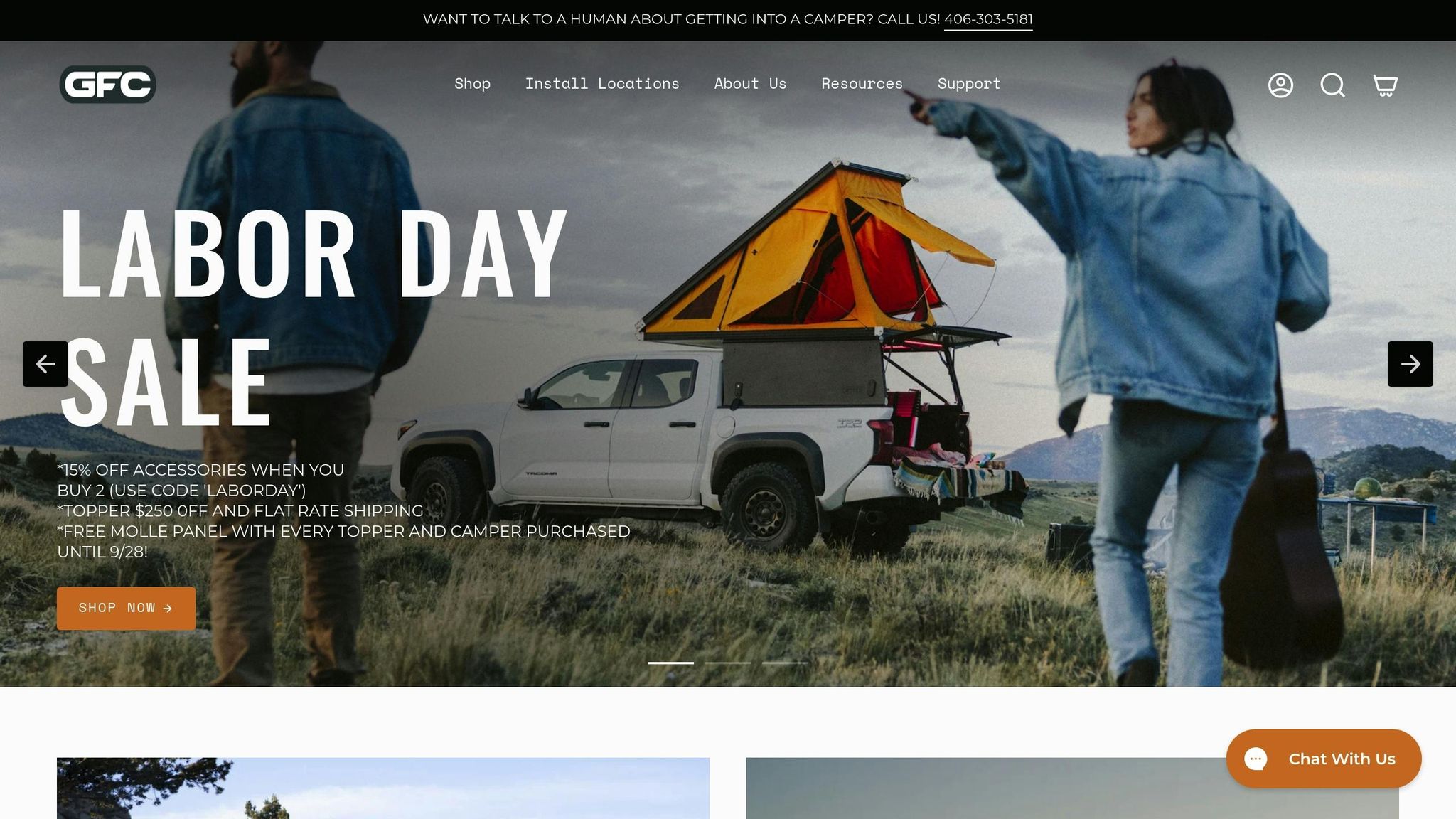

CNC robot: How a Cobot Controls Entire CNC Machining Cell at Go Fast Campers

Types of Robotic Arm CNC Machines

The design and configuration of robotic arms play a crucial role in shaping their performance in manufacturing. Each type has unique strengths, determined by how their joints, motors, and mechanical systems are arranged.

Articulated Arms

Articulated arms are some of the most flexible robotic CNC machines, equipped with 4 to 7 rotary joints. This multi-joint design allows them to navigate tight spaces, work around obstacles, and handle complex 3D tasks. Their wide range of motion makes them ideal for machine tending tasks, such as loading and unloading parts from CNC machines positioned at different angles. However, their flexibility comes with trade-offs. The added weight from multiple joints can limit their suitability for extremely high-speed operations, and they require larger workspaces to fully utilize their range of motion.

SCARA Robots

SCARA robots (Selective Compliance Assembly Robot Arm) are designed with a parallel-axis configuration, featuring two rotary joints and one linear joint. This setup provides "selective compliance", meaning the arm stays rigid during vertical movements while maintaining flexibility in horizontal motions. SCARA robots excel in tasks that demand quick, precise horizontal movements, such as assembly, pick-and-place operations, and inspection tasks in CNC machining environments. On the flip side, their vertical reach and 3D maneuverability are limited, making them less effective for jobs requiring extensive spatial flexibility. Additionally, their payload capacity is generally lower compared to articulated arms of similar size.

Delta Robots

Delta robots feature a parallel arm design, with three motors mounted at the base connected to lightweight arms that meet at a single end effector. This structure enables exceptionally fast and precise movements, making them perfect for lightweight tasks like pick-and-place, sorting, and packaging. However, their speed comes at the cost of a smaller working area and reduced payload capacity. Delta robots are best suited for handling lighter objects within a confined range of motion.

When it comes to precision, high-end CNC machines typically achieve accuracy levels between 0.02 mm and 0.05 mm. In contrast, industrial robots - including articulated, SCARA, and delta types - generally offer precision ranging from 0.1 mm to 0.2 mm. These robots prioritize repeatability over absolute accuracy. Understanding these configurations is key to selecting the right robotic solution to complement precision CNC machining in modern manufacturing environments.

How Robotic Arm CNC Machines Work in Manufacturing

Robotic arm CNC machines combine the precision of CNC technology with the adaptability of robotic systems, streamlining manufacturing processes. These machines operate through a well-defined sequence that ensures efficiency and consistency.

Step-by-Step Process

The workflow begins with material preparation, where the robotic arm retrieves raw materials from storage or conveyor systems. Equipped with sensors, the arm positions materials with pinpoint accuracy, minimizing errors that can occur with manual handling.

In the loading phase, the robotic arm carefully places workpieces into CNC fixtures. This step relies on seamless coordination between the robot's control system and the CNC machine to ensure proper timing. The arm’s end effector - whether it’s a gripper, vacuum cup, or another specialized tool - secures the parts based on pre-programmed specifications.

Next comes the machining stage, where the CNC machine performs tasks like cutting, drilling, or milling. Meanwhile, the robotic arm may assist by applying coolant, removing chips, or performing other secondary tasks to support the machining process.

Once machining is complete, quality inspection takes place. Integrated sensors and vision systems check dimensions, surface finishes, and potential defects without interrupting the production line. This allows the robotic arm to separate flawless pieces from those needing rework.

Finally, in the unloading and finishing phase, the robotic arm removes the completed parts and handles post-processing tasks such as deburring, cleaning, or even packaging the products.

This structured cycle lays the groundwork for smooth operation, but achieving consistent performance hinges on proper setup.

Setup Requirements

A reliable setup is key to ensuring these machines perform effectively. The workspace must accommodate the robotic arm’s full range of motion while adhering to OSHA safety standards. This includes creating a designated safety zone with emergency stops and clear sight lines for monitoring.

Power and infrastructure are critical considerations. Industrial robotic arms typically require a three-phase power supply, and systems with pneumatic grippers may also need compressed air. A robust network infrastructure using industrial Ethernet protocols facilitates communication between the robot controller, CNC machine, and other plant systems.

Programming and integration are handled through tools like teach pendants, offline simulation software, or direct CAD integration. These methods define motion paths, operational commands, and error-handling processes. They also account for tool changes and part variations, often linking to existing MES or ERP systems for production tracking.

To ensure precision, calibration and testing are essential. This involves setting reference points, verifying tool center points, and conducting trial runs with sample parts. Depending on the complexity of the setup, calibration can be time-intensive and may need to be repeated periodically. Temperature compensation algorithms are sometimes necessary to maintain accuracy when thermal fluctuations occur.

Finally, maintaining controlled environmental conditions - such as temperature, humidity, and airflow - is crucial. This helps protect sensitive components and ensures consistent performance, especially given the heat generated by motors and controllers.

sbb-itb-b5aecec

Pros and Cons of Robotic Arm CNC Machines

Robotic arm CNC machines bring a mix of benefits and challenges to the table. Weighing these factors carefully can help manufacturers determine if this technology aligns with their production goals and financial plans.

Advantages and Disadvantages

| Advantages | Disadvantages |

|---|---|

| Consistent Precision: Minimizes human error in handling and positioning, ensuring high repeatability. | High Initial Investment: Requires a significant upfront cost, along with expenses for setup, installation, and employee training. |

| Continuous Operation: Can run without breaks, increasing output compared to manual processes. | Complex Programming: Demands specialized expertise for programming and setup, which can be time-consuming. |

| Enhanced Safety: Keeps workers out of hazardous environments, reducing workplace injuries. | Limited Flexibility: Reprogramming for new tasks is time-intensive, limiting adaptability. |

| Labor Cost Reduction: Reduces dependency on highly skilled operators, potentially lowering labor expenses. | Maintenance Needs: Requires frequent calibration and regular component replacement to maintain efficiency. |

| Improved Quality Control: Built-in sensors can detect defects during production, improving overall quality assurance. | Space Requirements: Needs additional floor space to accommodate safety zones and the robot’s full range of motion. |

These pros and cons provide a framework for manufacturers to assess the value of robotic arm CNC machines. The precision they offer is a huge advantage for industries where tight tolerances are essential. Unlike human operators, these machines don’t tire, which means they can run continuously, leading to higher throughput, fewer rejected parts, and less wasted material.

On the flip side, the financial commitment is a major hurdle, especially for smaller manufacturers. Beyond the cost of the machine itself, companies must consider expenses for facility upgrades, safety systems, and employee training. The technical complexity is another factor, as programming these machines requires expertise in both CNC operations and robotics. Adapting to changes in production can also be a slow process, given the time needed for reprogramming. Maintenance is another ongoing cost, as robotic arms rely on servo motors, encoders, and mechanical joints that need regular inspections and adjustments. Additionally, the physical space required for these systems can be a challenge due to the need for safety zones around the equipment.

For manufacturers, whether robotic arm CNC machines are a good fit depends largely on production volume and part standardization. High-volume operations with consistent part designs tend to see the most benefits, while smaller-scale or highly varied production might find traditional methods more cost-effective. Careful evaluation of these factors is key to selecting a system that meets both production demands and budget limitations.

How to Choose the Right Robotic Arm CNC Machine

When selecting a robotic arm CNC machine, it's essential to focus on specifications like payload capacity and repeatability to ensure efficient production and a solid return on investment (ROI).

Key Considerations

- Payload Capacity: This refers to the maximum weight the robotic arm can handle, which includes both the workpiece and the end-of-arm tooling (EOAT).

- Precision vs. Repeatability: While precision is important, many applications prioritize repeatability - how consistently the robot can perform the same task over time - over absolute accuracy.

These factors serve as a foundation for making an informed choice and can be further refined with input from industry professionals.

Leverage the Machine Shop Directory

The Machine Shop Directory is a valuable resource, listing over 200 highly-rated U.S. machine shops that specialize in precision CNC machining and custom fabrication. Whether you're looking to integrate a robotic arm CNC system into your operations or outsource machining tasks, this directory connects you with seasoned experts who can guide you toward the best solution for your specific needs.

Conclusion

Robotic arm CNC machines bring together the accuracy of traditional CNC systems and the adaptability of robotic technology. This combination allows manufacturers to achieve consistent, high-quality results while reducing both labor costs and production times.

The three primary types of robotic arms - articulated arms, SCARA robots, and delta robots - each offer unique strengths tailored to various manufacturing needs. Key components like sensors, controllers, and end-of-arm tooling play a crucial role in defining the system's overall capabilities and performance.

When selecting a system, factors like payload capacity and repeatability take center stage. These determine not just the machine's ability to perform precise tasks but also how reliably it can maintain performance over time. Instead of focusing solely on achieving the highest precision, manufacturers should emphasize consistency across long-term operations.

A thorough understanding of these systems is essential for smooth integration into existing workflows. Proper planning - covering workspace setup, safety measures, and strategies for uninterrupted operation - is critical. The rewards, including around-the-clock operation, reduced errors, and enhanced worker safety, make robotic arm CNC machines an indispensable tool for staying competitive in modern manufacturing.

FAQs

Which industries benefit the most from robotic arm CNC machines, and why?

Robotic arm CNC machines have become indispensable in industries like automotive, aerospace, electronics, and medical device manufacturing. These machines are valued for their ability to provide precise machining, boost efficiency, and create safer working environments.

Take the automotive industry, for instance. Robotic arms excel at tasks such as welding and surface finishing, completing them with impressive speed and accuracy. This ensures consistent quality while also cutting down on production expenses. In aerospace and medical device manufacturing, robotic CNC systems play a vital role in crafting intricate, high-tolerance components that are essential for both performance and safety.

How does the complexity of programming robotic arm CNC machines impact their use in manufacturing?

The programming demands of robotic arm CNC machines can significantly affect how smoothly they fit into current manufacturing processes. In many cases, working with robots from various manufacturers or updating older CNC systems requires advanced programming expertise. This can lead to longer setup times and higher upfront costs.

That said, newer programming tools like CAD, CAM, and STEP-NC protocols are making things much simpler. These technologies are helping robotic CNC systems become more adaptable, allowing businesses to meet a broader range of manufacturing needs while optimizing workflows and boosting overall efficiency.

What should I consider to calculate the return on investment (ROI) for a robotic arm CNC machine?

When figuring out the ROI for a robotic arm CNC machine, several factors come into play. Start with the initial investment, which includes the cost of the equipment, tooling, and installation. Then, account for ongoing expenses like energy consumption, maintenance, and potential repair costs. On the flip side, weigh the benefits such as increased productivity, better product quality, lower labor expenses, and any financing options or tax incentives that might be available.

Another important metric is the payback period, which typically ranges from 12 to 36 months. This helps estimate how quickly the investment will begin to pay off. By carefully analyzing these elements, you can gauge whether adding a robotic arm CNC machine makes financial sense for your business.