Top Certifications for Apparel Export Labeling

Certifications are a must-have for apparel exporters. They ensure compliance with international standards, from product safety and quality to ethical practices. Without them, manufacturers risk fines, shipment delays, or outright market rejection. For example, the FTC refunded over $140,000 in 2024 due to false "Made in USA" claims.

Here’s what you need to know:

- Mandatory certifications (e.g., U.S. care labeling rules, EU fiber composition standards) are legally required for market entry.

- Voluntary certifications (e.g., OEKO-TEX, SEDEX, ISO 9001) enhance product credibility and boost sales by meeting consumer expectations for safety and sustainability.

- Top markets like the U.S., EU, and Asia have unique labeling and certification requirements, such as bilingual labels in Canada or flammability standards in the UK.

Key certifications to consider:

- OEKO-TEX Standard 100: Tests for harmful substances in textiles.

- SEDEX: Focuses on ethical labor practices.

- ISO 9001: Ensures consistent product quality.

Proper documentation, certified manufacturing partners, and staying updated on regulations are non-negotiable for success. Certifications aren’t just about compliance - they’re a smart way to build trust and expand globally.

Webinar: Regulations for exporting textile & footwear to EU

Regulatory Requirements for Apparel Origin Labeling

Understanding the rules for apparel origin labeling is a must for exporters navigating international markets. Different regions enforce their own sets of standards to protect consumers and ensure transparency, making it essential to grasp the varied regulations in play. Here's an overview of the key requirements in some major export markets.

Required Labeling Standards in Major Export Markets

The United States has some of the strictest labeling standards worldwide. The Federal Trade Commission (FTC) requires labels to include fiber content, country of origin, manufacturer identification, and care instructions for all textile products. The U.S. stands out as the only major country that mandates country of origin labeling for all products. For a product to carry the "Made in USA" label, it must be "all or virtually all" made domestically. Non-compliance can lead to penalties, shipping delays, and reputational harm.

In contrast, the European Union operates under Regulation (EU) 1007/2011, which standardizes fiber composition labeling across member states. However, country-of-origin requirements are not harmonized, meaning exporters must research individual regulations for each country within the bloc. While care labeling isn’t mandatory, it’s generally recommended to avoid issues.

Canada poses unique challenges, particularly with its bilingual labeling requirements and the need for precise invoice details. U.S. exporters often face difficulties proving product origin or providing detailed commercial invoices, which can result in border delays and compliance setbacks.

In the United Kingdom, fiber content labeling is mandatory, and accurate country-of-origin disclosure is critical to prevent misleading consumers. Additionally, the UK requires flammability labels for specific garments, particularly children's and baby clothing.

Asian markets like Japan, China, and South Korea have highly specific labeling rules tailored to their local requirements. Exporters need to pay close attention to language and cultural nuances when targeting these regions.

Country of Origin Labeling Regulations

Country-of-origin labeling plays a critical role in trade compliance. Mislabeling can result in fines, additional duties, or other penalties. Certifications that verify compliance with trade standards are often necessary. For example, under the USMCA agreement, "yarn-forward" rules require that all yarn components used in apparel originate from within the agreement region. Specific parts of apparel, such as pocket bag fabric, must also use materials sourced from the USMCA region.

To illustrate, a white t-shirt made in Vietnam can be labeled as either "Vietnam" or "Made in Vietnam." However, if the shirt features "France" printed on it, the label must clearly state "Made in Vietnam" to accurately reflect its production location and avoid misleading consumers.

In Australia, fiber content labeling is generally optional, except in New South Wales where it’s required. The country enforces mandatory country-of-origin labeling with different rules depending on whether items are made entirely domestically, partially domestically, or fully imported.

For companies exporting to multiple markets, it’s crucial to recognize that regulations vary widely and are subject to change, especially in dynamic regions like Europe. Collaborating with local suppliers or compliance experts can help ensure that labels meet the requirements of key markets. Including translations, such as English and Chinese, can also streamline operations across diverse regions.

The intricate nature of these regulations highlights the importance of proper certifications and compliance documentation. These tools are essential for navigating the complexities of global apparel exports successfully.

Top Certifications for Apparel Export Labeling

Certifications play a crucial role in ensuring compliance and boosting market appeal for apparel exports. While meeting regulatory requirements is essential, additional certifications can help companies exceed basic standards and build stronger consumer trust. This sentiment is well-supported by industry insights.

"While mandatory regulatory compliance builds the foundation of market access, voluntary certifications have become indispensable for a lot of companies in the textile industry." - Yujing Pan, Subject Matter Expert in Product Compliance, Enhesa

Consumer preferences also reflect this trend, with nearly 85% favoring textiles that come with safety certifications. Moreover, products that emphasize sustainability often see a 25% increase in sales.

OEKO-TEX Standard 100

OEKO-TEX Standard 100 is one of the most widely recognized certifications in the textile world. It ensures that textiles are tested for over 1,000 harmful substances. By meeting international safety benchmarks, this certification provides an added layer of quality assurance. For apparel exporters, having the OEKO-TEX label can be a key selling point in markets where consumer health and safety are top priorities.

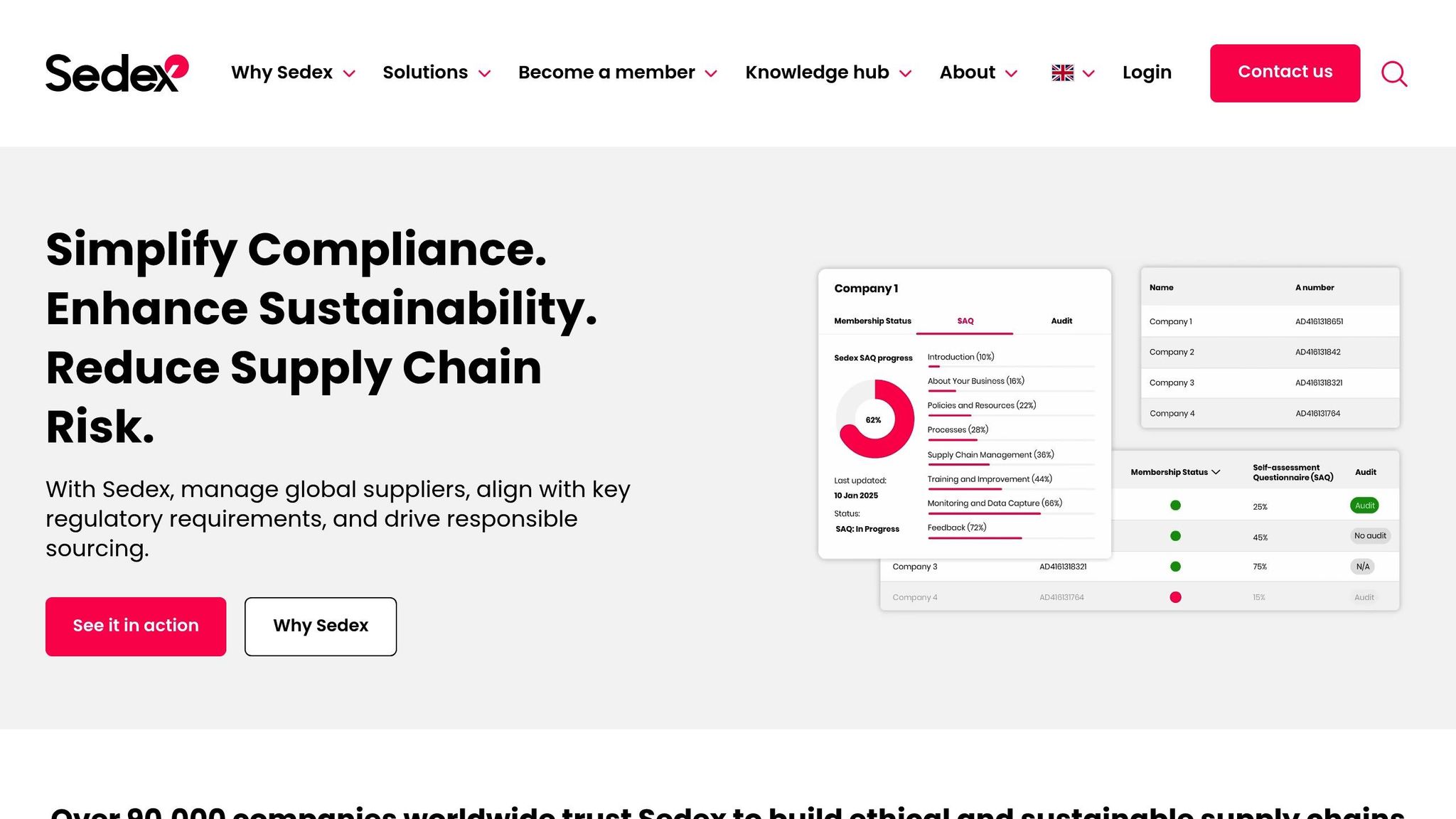

SEDEX Certification

SEDEX (Supplier Ethical Data Exchange) is all about ethical practices and better labor conditions within global supply chains. For exporters aiming to meet the demands of markets that emphasize ethical sourcing, SEDEX certification serves as strong proof of responsible manufacturing.

ISO 9001 for Quality Management

ISO 9001 certification focuses on maintaining consistent product quality and efficient manufacturing processes. This global standard reassures buyers that production workflows are well-controlled, which is especially important for fulfilling large orders or securing long-term supply contracts.

Together, these certifications address key global market demands - consumer safety, product quality, and ethical production - helping apparel exporters stand out in an increasingly competitive landscape.

sbb-itb-b5aecec

Certification Requirements and Benefits Comparison

Expanding on the regulatory context discussed earlier, a closer look at certification requirements helps exporters navigate global markets more effectively. By understanding the differences between certifications, businesses can choose the standards that best align with their target markets and goals.

Certifications fall into two main categories: mandatory certifications, which are legally required for market entry, and voluntary certifications, which can boost competitiveness and build consumer trust.

For example, U.S. laws require detailed labels that specify fiber content, manufacturer information, product origin, and care instructions. In contrast, EU regulations focus on providing clear fiber composition in descending order. Earlier sections provide a deeper dive into U.S. and EU-specific requirements.

One standout certification is OEKO-TEX, which spans over 35,000 companies worldwide and issued 24,205 certificates last year - marking a 13% increase. The OEKO-TEX website attracts around 5,000 daily visits from over 200 countries, highlighting its global appeal.

The table below outlines key certifications, their areas of focus, and the benefits they offer, helping exporters align compliance efforts with market expectations.

Certification Comparison Table

| Certification | Region of Recognition | Mandatory/Voluntary | Area of Focus | Key Benefits |

|---|---|---|---|---|

| OEKO-TEX Standard 100 | Global | Voluntary | Safety Testing | Screens for over 1,000 harmful substances; often exceeds national and international safety standards |

| SEDEX | Global | Voluntary | Ethical Labor Practices | Promotes ethical labor conditions and responsible supply chain practices |

| ISO 9001 | Global | Voluntary | Quality Management | Ensures consistent product quality and efficient workflows |

| CPSC Certification | United States | Mandatory | Consumer Product Safety | Enforces safety standards for consumer goods, including textiles |

| ASTM Standards | US and International | Voluntary | Testing Methods | Develops widely adopted consensus standards for testing |

| EU Textile Labeling | European Union | Mandatory | Fiber Composition | Requires clear labeling of fiber content for consumer transparency |

| US Care Labeling Rule | United States | Mandatory | Care Instructions | Specifies care guidelines for clothing and certain fabrics |

| Flammable Fabrics Act | United States | Mandatory | Flammability Standards | Regulates flammability for textiles, especially children’s sleepwear |

This comparison highlights key trends in certification requirements. Global voluntary certifications like OEKO-TEX, SEDEX, and ISO 9001 go beyond legal obligations to focus on product safety, ethical practices, and quality management. These certifications can provide a competitive edge, especially in markets where consumers value safety and responsible production.

On the other hand, mandatory certifications vary by region. U.S. regulations emphasize detailed labeling, care instructions, and safety standards, while EU rules prioritize fiber composition transparency. For exporters targeting multiple markets, understanding these regional distinctions is critical.

Voluntary certifications, such as OEKO-TEX, offer manufacturers flexibility to align with specific market demands and brand strategies. As consumer interest in certified products grows, these voluntary standards are becoming increasingly important for staying competitive in the global market.

Compliance Best Practices for Apparel Exporters and Manufacturing Partners

Ensuring compliance with global labeling and certification standards goes beyond simply obtaining certificates. Successful apparel exporters establish structured systems to maintain adherence to regulations while fostering dependable supply chain partnerships.

Keeping Accurate Certification Documentation

Maintaining organized and detailed records is a cornerstone of compliance. Exporters need robust documentation systems to track certification validity, renewal timelines, and updates from regulatory bodies like the FTC and CPSC.

Key practices include:

- Keeping digital copies of certifications with secure backups.

- Monitoring renewal dates to prevent lapses.

- Organizing files by market region and product category.

Testing reports from accredited labs should be stored alongside related product batches, ensuring traceability during inspections. Subscribing to regulatory update services from the FTC and CPSC is another proactive step to stay informed about shifting requirements.

Effective documentation also covers supplier certifications, material sourcing records, and production batch details. For example, a small apparel brand in India transitioned to using organic dyes and recycled fibers, meeting sustainable textile standards. This meticulous compliance approach helped them secure deals with major U.S. brands and double their revenue within a year. Such practices lay the groundwork for thorough partner verification.

Working with Certified Manufacturing Partners

Accurate documentation is just the beginning. Verifying manufacturing partners is equally crucial. Exporters should go beyond surface-level checks by requesting certification copies and confirming their authenticity directly with accrediting organizations.

Understanding what each certification entails is vital, rather than treating it as a mere formality.

Regular audits are another critical element of compliance. A strong audit program includes both scheduled reviews and surprise spot checks, focusing on production processes, material sourcing, and quality control. Clear communication protocols - such as routine compliance updates and procedures for addressing certification changes - help maintain strong, long-term partnerships.

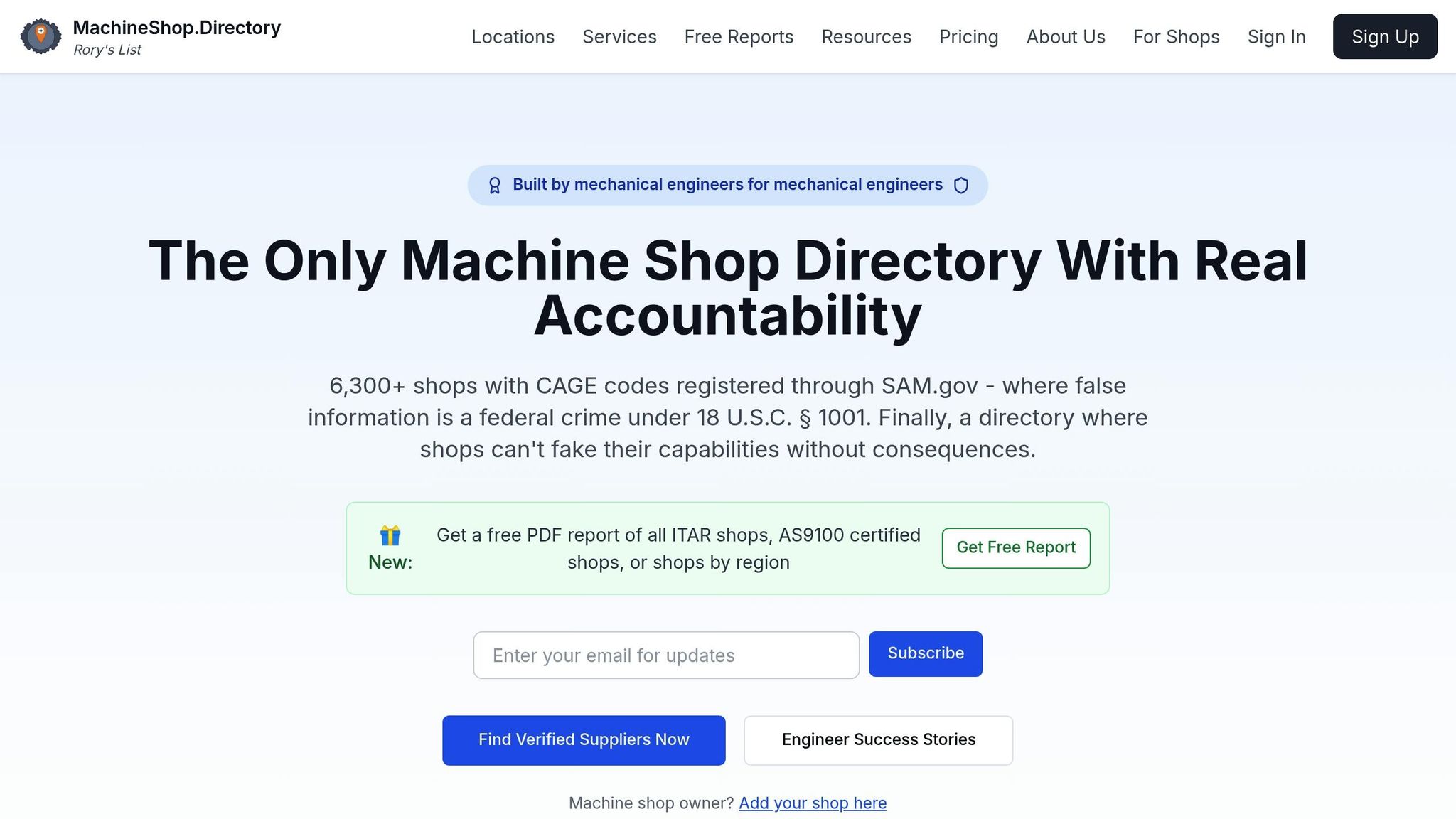

Using Resources Like the Machine Shop Directory

Finding the right manufacturing partners is easier with tools like specialized directories. For instance, the Machine Shop Directory lists over 200 top-rated machine shops specializing in precision CNC machining and custom fabrication. These services can be essential for apparel production components.

This directory allows exporters to strategically compare providers based on their certifications, production capabilities, and industry expertise. It’s especially useful for sourcing custom hardware, specialized fasteners, or precision-cut fabric components that require strict dimensional tolerances. By reducing the time spent researching and vetting manufacturers, exporters can focus on building efficient partnerships.

As certification standards evolve, having access to up-to-date information about partner capabilities ensures exporters can quickly adapt to market demands. For example, directories that include current certification statuses - like ISO 9001 for quality management - streamline integration with compliance programs.

Collaborating with certified partners who understand regulatory requirements not only reduces risks but also boosts operational efficiency. This advantage leads to faster time-to-market and ensures smoother adherence to compliance standards.

Conclusion

Certifications play a crucial role in the global apparel export industry, ensuring compliance with ethical, social, and environmental standards. With financial risks such as penalties reaching up to 2% of global revenue in states like California for Extended Producer Responsibility (EPR) or labor law violations, adhering to these standards is not just a legal requirement but a business necessity. Certifications like OEKO-TEX Standard 100, SEDEX, ISO 9001, CPSC, and ASTM standards are essential for legal market entry while also demonstrating a commitment to quality and ethical practices.

Beyond regulatory compliance, certifications offer significant business advantages. They open doors to broader markets, strengthen customer loyalty, boost productivity, and enhance overall brand reputation. These benefits highlight the importance of maintaining certified operations in the competitive global marketplace.

Effective compliance strategies go beyond ticking boxes. They require thorough documentation, partnerships with certified manufacturers, and smart allocation of resources to meet ever-changing regulations.

Certifications are more than just regulatory tools; they are a pathway to operational excellence. As consumers increasingly demand transparency and ethical production, certifications become a key differentiator, helping businesses stand out in crowded markets. They also build the trust that international buyers now expect from their supply chain partners.

For apparel exporters and manufacturers, prioritizing certifications and strong compliance systems is not just about meeting obligations - it’s a strategic investment that drives sustainable growth in an industry where ethical practices are no longer optional but essential.

FAQs

What’s the difference between mandatory and voluntary certifications for apparel exports?

Certifications can be divided into two main types: mandatory and voluntary.

Mandatory certifications are required by law and enforced by government authorities. These certifications ensure that products comply with specific safety, health, or environmental regulations. Without them, products cannot be legally imported, exported, or sold in the market.

Voluntary certifications, on the other hand, are not legally required. Companies often pursue these to demonstrate their commitment to areas like quality, ethical practices, or sustainability. While optional, these certifications can enhance a brand’s reputation and help establish trust with both consumers and business partners.

What steps should apparel exporters take to comply with country-of-origin labeling rules in global markets?

To meet country-of-origin labeling requirements, apparel exporters need to thoroughly understand the specific regulations for each market they plan to enter. Take the United States, for instance: products must display their country of origin clearly, using approved methods like die-sinking, molding, or durable stickers. These labels must be easy to find and read.

It's also crucial to stay informed about any exemptions or extra labeling rules that might apply to certain product categories. Reviewing official government resources and, if necessary, requesting binding rulings from customs authorities can help ensure everything is in order. Careful research and attention to these details can save exporters from expensive errors or shipping delays when dealing with international markets.

Why should apparel exporters work with certified manufacturing partners, and how can they confirm these certifications?

Working with certified manufacturing partners is crucial for apparel exporters. These certifications serve as proof of product quality, adherence to ethical labor practices, and compliance with international standards. Together, these elements help establish trust with customers while easing entry into global markets.

To verify a partner's certifications, it's important to go straight to the source. Check the certification's validity through official registries or directly contact the certifying organization for confirmation. Make sure the certification is current and aligns with the specific standards required by your target export market.