Top 7 DLP 3D Printing Software Tools

DLP 3D printing delivers high-precision parts quickly, making it ideal for complex geometries and custom projects. The software you choose is critical - it affects print quality, efficiency, and workflow integration. Here's a quick guide to the best tools:

- CHITUBOX: Free, supports most DLP printers, offers advanced support generation and model repair tools.

- Lychee Slicer: User-friendly, works with 750+ printers, and includes batch processing for high-volume tasks.

- PrusaSlicer: Open-source, handles both FDM and resin printing, with strong support generation and editing features.

- NanoDLP: Web-based, compatible with many printers, ideal for custom setups with advanced algorithms.

- Photon Workshop: Tailored for Anycubic printers, features customizable support settings and model preparation tools.

- Z-Suite: Optimized for Zortrax printers but supports others with custom settings, offering flexible support options.

- Creation Workshop: Open-source, budget-friendly option for prototyping.

Each software brings unique strengths, from slicing speed to support customization. Choose based on your printer compatibility, project needs, and budget.

CHITUBOX -The Best Slicer for your Resin 3D Printers?

How to Choose DLP 3D Printing Software

Picking the right DLP software can make or break your 3D printing experience. The right choice helps avoid failed prints, reduces waste, and speeds up production. Here's what to consider when evaluating your options:

Printer compatibility is a must. Make sure the software supports your specific printer model and its native file formats. This is especially important if you're working with multiple printer brands.

Slicing speed plays a big role in production efficiency. Look for software that slices complex models quickly, which is crucial for high-volume or iterative projects.

Support generation capabilities are key to successful prints. Choose software that can automatically identify where supports are needed and allows you to customize settings like density, contact points, and ease of removal. This reduces the risk of failed prints and cuts down on post-processing time.

Model repair functionality can save you hours of frustration. Software that automatically detects and fixes issues like non-manifold edges, holes, or intersections in CAD files will help you avoid crashes and wasted time.

The user interface can impact your productivity more than you'd think. Go for software with an intuitive layout that’s easy to learn but still offers advanced features for experienced users.

Integration with CNC workflows is vital if your shop uses hybrid manufacturing. The right software will sync 3D printing and machining processes, making it easier to create parts that combine both methods.

Material profiles and exposure settings are critical for print quality. Look for software offering both pre-set resin profiles and customizable exposure controls so you can fine-tune your prints.

Batch processing capabilities are a game-changer in production environments. Software that lets you queue multiple jobs, optimize layouts, and manage schedules can streamline prototyping and speed up production.

File format support is another important factor. Ensure the software works with universal formats like STL and OBJ, and, if possible, supports native CAD files for smoother integration into your workflow.

Don’t forget to assess your budget. Free software often covers the basics, while premium options may include features like cloud processing, team collaboration tools, and priority support. Subscription models spread out costs, while perpetual licenses require a larger upfront investment.

Finally, technical support and community resources are invaluable when issues arise. Choose software with reliable support, active user communities, and detailed documentation to help you troubleshoot problems quickly.

Take advantage of free trials or demos to test how well the software works with your printer and project requirements before making a commitment.

1. CHITUBOX

When it comes to enhancing DLP workflows, CHITUBOX stands out as a reliable and feature-packed slicing tool. It's a free software solution that's widely used in machine shops, thanks to its extensive compatibility and powerful features.

Printer Compatibility

CHITUBOX is designed to work with the majority of SLA, DLP, and LCD 3D printers on the market. It supports a wide range of brands, including AnyCubic, Creality, ELEGOO, EPAX, Flashforge, Longer3D, Peopoly, Phrozen, QIDI, SparkMaker, Voxelab, WanHao, and Zortrax.

Some of the most popular models it supports include:

- Flashforge Foto 8.9

- AnyCubic PHOTON MONO M7 PRO

- Phrozen Sonic Mighty 12K

- EPAX E10 14K

- ELEGOO Saturn 4 Ultra 16K

- CREALITY HALOT-X1

This broad compatibility allows users to standardize CHITUBOX across various printer brands, simplifying training and improving workflow efficiency. Beyond compatibility, CHITUBOX also boosts print quality with its advanced support tools.

Support Generation (Manual and Automatic)

CHITUBOX offers both automatic and manual support generation, giving users precise control over their prints. It provides two main auto-support modes:

- +All: Adds supports to all surfaces of the model.

- +Platform: Limits support generation to areas directly on the build platform.

For those using CHITUBOX Pro, the ChituAction feature can automate the entire model preparation process with a single click, saving time and reducing manual effort. Additionally, the Magic Support function intelligently places supports based on the model's geometry, making it especially useful for intricate designs.

If you need more control, manual tools let you adjust support placement, density, and contact points to suit specific materials and post-processing needs.

Model Repair and Editing Capabilities

CHITUBOX also includes tools to repair and edit models, reducing the need for additional CAD software. Features like hollowing, drilling drainage holes, and automated mesh repair help fix common issues quickly.

For machine shops working with large or complex designs, the Split and Boolean operations are invaluable. These tools allow you to divide large models into smaller sections or combine multiple parts, streamlining the path from design to final print.

2. Lychee Slicer

Lychee Slicer has earned its place in machine shops thanks to its combination of powerful features and an easy-to-use interface. Designed to cater to both beginners and seasoned professionals, it simplifies the slicing process without compromising on functionality. Let’s dive into its standout features, starting with printer compatibility.

Printer Compatibility

Lychee Slicer works with over 750 printers, with its latest compatibility update dated June 27, 2024. It covers a broad range of resin-based DLP and SLA printers, including popular models like the Anycubic M3, Creality Halot One, and SparkMaker. If your specific printer isn’t on the list, you can still define custom build volume settings, making it adaptable for unique or modified setups. This flexibility is a game-changer for machine shops that rely on specialized equipment, as it eliminates the hassle of juggling multiple slicing programs.

Support Generation (Manual and Automatic)

Lychee Slicer simplifies support generation with both automatic and manual options. The automatic feature creates support structures for an entire model with just one click, saving time on intricate designs. For more control, the software offers adjustable presets - Light, Medium, and Heavy - where you can tweak parameters like tip diameter and length to suit your needs. You can also manually adjust placement, size, shape, and visibility to align with specific material properties or post-processing requirements. Combining automated generation with manual fine-tuning ensures optimal results while minimizing material waste.

Batch Processing Capabilities

For high-volume projects, Lychee Slicer Pro includes a Batch Tool that streamlines repetitive tasks. This feature allows you to process multiple models at once, applying functions such as file name adjustments, topology repairs, uniform scaling, axis rotations, and automatic support generation based on your presets. The tool accepts various file formats, including STL, OBJ, 3MF, and LYS, making it versatile for different workflows. Additionally, the Multiplate feature lets you manage multiple build plates within a single project, further enhancing productivity for large-scale operations.

3. PrusaSlicer

PrusaSlicer is a free, open-source tool that has gained traction for its ability to handle both FDM and resin printing. Its cost-free access and an active user community make it especially appealing for machine shops tackling resin-based projects.

Printer Compatibility

PrusaSlicer comes with pre-configured profiles for well-known resin printers, such as the Prusa SL1 and SL1S SPEED. It also allows users to create custom profiles, tailoring settings like build volumes, layer heights, exposure times, and lift speeds. This flexibility makes it a solid choice for those using modified or specialized equipment.

One of its standout features is its focus on support generation, which is crucial for achieving successful prints.

Support Generation (Manual and Automatic)

PrusaSlicer strikes a balance between automatic and manual support creation. The automatic mode analyzes a model's geometry and generates supports based on factors like overhang angles and spacing. For those who prefer more control, manual adjustments are available, allowing for fine-tuning. A 3D preview feature lets users visualize contact points, making the process more intuitive.

Model Repair and Editing Tools

The software also includes tools to fix common issues like non-manifold edges or holes in a model. Beyond repairs, it offers editing features for scaling, rotating, and mirroring designs. For larger models, its built-in cut and split tools simplify preparation for printing.

Batch Processing Features

PrusaSlicer makes handling multiple files efficient with its batch processing capabilities. Its plater tool arranges multiple STL files on the build plate, optimizing spacing and orientation. Users can save project files for repeatable production runs, and for advanced automation, the command-line interface streamlines slicing tasks.

PrusaSlicer combines ease of use with powerful features, making it a reliable tool for resin printing workflows.

4. NanoDLP

NanoDLP is a web-based platform designed to control and monitor SLA, LCD, and DLP 3D printers. It can be accessed from any device connected to the network, making it a versatile option for both custom fabrication shops and DIY enthusiasts. Its flexibility and ease of access are complemented by its compatibility with a wide range of printers, which we'll explore below.

Printer Compatibility

NanoDLP supports most SLA and DLP printers and officially works with models like the Phrozen Make, Make XL, Microlay DentalFab, SOLIDRAY 2, and the mUVe 3D series. It's particularly popular among DIY builders, often paired with a Raspberry Pi for added functionality. Additionally, the NanoDLP controller board can be used to upgrade many existing LCD and SLA printers.

For manufacturers with unique needs, NanoDLP also offers customized software solutions tailored to specific printer models. However, it's worth noting that some printers, such as the Elegoo Mars 4 DLP, require additional hardware to work with NanoDLP due to the absence of an HDMI port.

Support Generation (Manual and Automatic)

NanoDLP, together with its slicer tool NanoSupport, provides automatic support generation using advanced algorithms. These algorithms are designed to improve print quality and success rates, offering three support types - small, medium, and large - that can be customized in real time. While this feature is powerful, beginners may find the interface a bit challenging to navigate. Additionally, manual freehand rotation could make precise support placement more difficult.

NanoDLP’s ability to integrate with custom hardware setups makes it a strong choice for those looking to tailor their printing processes to specific workflows.

sbb-itb-b5aecec

5. Photon Workshop

Photon Workshop is Anycubic's dedicated slicer software, designed specifically for its Photon DLP and LCD resin printers. The latest version, 3.0.0, introduces improved tools for generating supports and preparing models for precise, custom fabrication.

Printer Compatibility

Photon Workshop is built to work seamlessly with Anycubic's range of resin printers, including the Photon Mono series, Photon Ultra, and other DLP models. It’s fine-tuned for Anycubic’s printer profiles and resin settings, ensuring a smoother workflow within their ecosystem. However, it doesn't offer the broader compatibility of universal slicers, making it a more specialized tool for Anycubic users.

Support Generation (Manual and Automatic)

Version 3.0.0 of Photon Workshop gives users the flexibility to generate supports either automatically or manually, striking a balance between ease of use and control. The automatic support feature can handle the entire model or focus solely on areas like the build plate and bottom sections, depending on your needs. For those who prefer more control, the manual system allows you to place and tweak support anchor points directly.

The software also includes advanced support settings. Users can choose from preset profiles ranging from light to heavy, or dive into custom configurations for more tailored results. A standout feature, "Check Islands", visually flags areas that need additional support: green indicates sufficient support, yellow suggests marginal coverage, and red highlights areas that require reinforcement. For intricate models, you can combine auto-generated supports with manual adjustments, fine-tuning angles and anchor distances to ensure a stable and successful print.

6. Z-Suite

Z-Suite is Zortrax's slicing software designed for versatility. While it remains optimized for Zortrax's flagship UV LCD printers, it now extends support to a wider range of third-party devices.

Printer Compatibility

Z-Suite was originally tailored for Zortrax's UV LCD printers, including the Inkspire and Inkspire 2. However, it now accommodates third-party LCD printers by allowing users to input custom printer parameters. According to All3DP, this update makes Z-Suite a viable option for budget-friendly systems like the Anycubic Photon and Elegoo Mars. It's worth noting that non-Zortrax users might not have access to some advanced features. This expanded compatibility enhances its appeal, particularly when combined with Z-Suite 2's advanced support generation tools.

Support Generation (Manual and Automatic)

Z-Suite 2 builds on its printer compatibility with robust support generation capabilities. It offers both automatic and manual options, giving users flexibility to handle intricate models. The automatic system creates supports based on an angle threshold, while the manual option lets users tweak settings like the initial angle and the spacing between support pillars. Additional customization features include adjusting the tip type, depth, size, and length of support pillars. A specialized AREA support feature is also available, making it ideal for organic and irregular shapes.

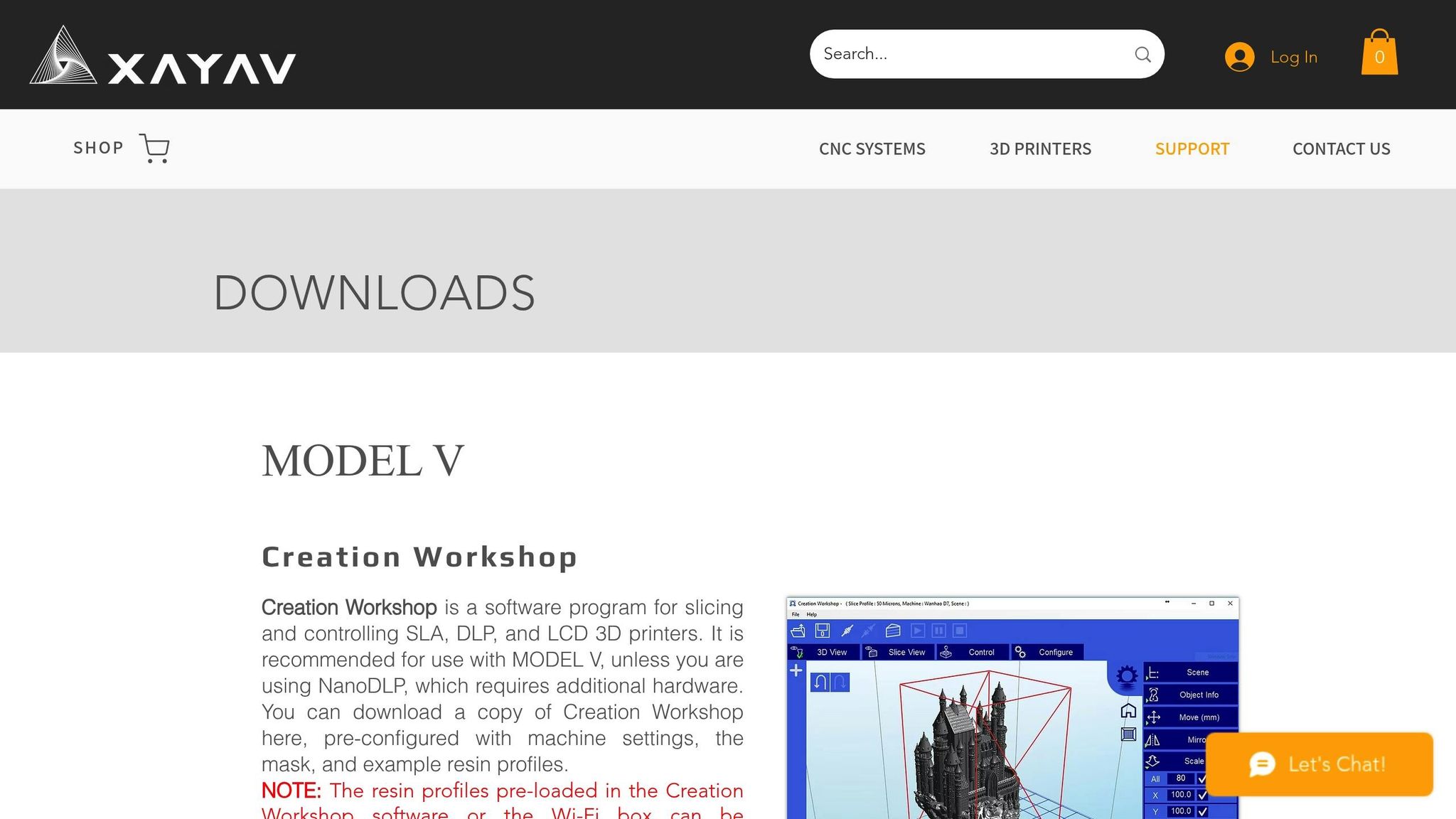

7. Creation Workshop

Closing out the list is Creation Workshop, an open-source software tailored for DLP 3D printing. It’s particularly geared toward those looking for a budget-friendly way to handle prototyping tasks.

While detailed information on its features - like support generation, printer compatibility, and model repair tools - is somewhat limited, users can explore its official documentation or engage with community forums to stay updated on its capabilities.

Its open-source framework makes it an attractive choice for users who value flexibility and customization in their DLP 3D printing processes.

Feature Comparison Table

Here's a quick look at the operating system compatibility for some of the top DLP software tools:

| Software Tool | Supported Operating Systems |

|---|---|

| CHITUBOX | Unspecified |

| Lychee Slicer | Not mentioned |

| PrusaSlicer | Windows, macOS, Linux |

| NanoDLP | Not mentioned |

| Photon Workshop | Not mentioned |

| Z-Suite | Not mentioned |

| Creation Workshop | Not mentioned |

Note: The table shows a mix of detailed and missing information about OS compatibility, highlighting the diverse software environments you might encounter when using DLP tools in your fabrication processes.

Using DLP Software in Custom Fabrication Workflows

DLP 3D printing software has become a game-changer for machine shops aiming to expand their custom fabrication capabilities. By bridging the gap between traditional CNC machining and additive manufacturing, these tools streamline production workflows and open up new possibilities.

One of the standout benefits of using DLP software is its ability to support rapid prototyping. With DLP printing, machine shops can produce intricate geometries at impressive speeds, cutting both costs and material waste. This efficiency shortens development cycles and ensures that prototypes are ready for testing much faster than with traditional methods.

Modern DLP software also excels in precision, making it ideal for creating tooling and fixtures. Machine shops can now produce jigs, fixtures, and inspection gauges with tight tolerances - at a fraction of the cost of machining them from metal. This capability is especially useful for transitioning from design validation to full-scale production while keeping expenses in check.

For engineers, DLP software simplifies design validation. It allows for rapid iteration, helping identify manufacturing issues early in the process. This proactive approach reduces the risk of costly rework and keeps projects on schedule.

DLP printing also shines in low-volume production of complex parts. Components with intricate internal features or challenging geometries, which might be difficult or expensive to produce using CNC machining, can often be created more efficiently with DLP technology.

The evolution of DLP resin materials has further expanded its applications. Engineering-grade polymers now meet higher performance standards, enabling the production of functional end-use parts alongside traditional metal components. These advancements align with the growing demand for cost-effective and high-performance solutions in custom fabrication.

Quality control is another area where DLP software proves its worth. Machine shops can design custom inspection fixtures or go/no-go gauges tailored to specific geometries, ensuring consistent quality across production runs without incurring the higher costs of traditional methods.

For shops specializing in custom fabrication, DLP software also facilitates seamless hybrid workflows. It allows for the integration of printed and CNC-machined components into complex assemblies. By generating precise support structures and optimizing part orientation, DLP software ensures that printed parts align perfectly with machined pieces, resulting in efficient and cohesive assemblies.

Beyond printing, the software enhances workflow efficiency by directly importing CAD files. This ensures design accuracy and reduces the chances of errors, speeding up the transition from concept to production.

Additionally, tools like the Machine Shop Directory connect shops with specialized DLP printing services. This network broadens their capabilities, enabling them to offer comprehensive fabrication solutions while staying at the forefront of additive manufacturing technologies.

Conclusion

Selecting the right DLP 3D printing software plays a key role in helping machine shops enhance their additive manufacturing capabilities and remain competitive. The seven software tools discussed in this guide each bring distinct advantages. From the intuitive design of CHITUBOX to the advanced control options in NanoDLP, these tools offer the flexibility to match specific workflow needs.

As highlighted, machine shops across the U.S. increasingly see DLP software as an integral part of their operations. These tools allow seamless integration of additive manufacturing with traditional CNC machining, enabling hybrid workflows that combine speed and precision. This not only streamlines production but also supports custom fabrication demands, transforming how shops handle unique projects.

DLP printing is also a cost-effective solution, especially for prototyping and small-batch production runs. With faster turnaround times and the ability to maintain high precision, shops can meet client expectations while using engineering-grade resins to produce functional parts. This capability complements traditional metal component production, offering more versatile manufacturing options.

As DLP technology continues to evolve, the software becomes more tailored to industry needs. Features like direct CAD file imports, automated support generation, and precise control of print settings are now essential for maintaining precision in fabrication. These tools integrate seamlessly with CNC workflows, ensuring that DLP printing enhances rather than disrupts traditional operations.

For machine shops looking to expand their additive manufacturing capabilities, investing in reliable DLP software is a strategic move. Whether it's creating inspection fixtures, complex prototypes, or end-use parts, the right software provides the foundation for efficient and successful DLP printing. This approach strengthens the hybrid manufacturing strategies that are central to modern machine shop operations.

FAQs

How can I choose the best DLP 3D printing software for my printer?

To choose the best DLP 3D printing software for your printer, start by reviewing the manufacturer's recommendations. Many brands provide software specifically designed for their printers, ensuring everything works together smoothly. For instance, some printers include dedicated software that enhances performance and simplifies the printing process.

If you're exploring third-party options, focus on software that aligns with your printer's resolution, firmware, and file format requirements. Well-known options like ChiTuBox and Lychee are popular for their broad compatibility and ability to fine-tune settings for various models, helping you achieve excellent print quality. Just make sure the software integrates well with your printer to avoid any hiccups during printing.

What are the benefits of using open-source DLP 3D printing software instead of paid options?

Open-source DLP 3D printing software offers a range of benefits that make it a popular choice among users. One standout feature is its flexibility - users can tweak and adjust the software to fit their specific hardware setups or unique project needs. This level of personalization can lead to better performance and greater adaptability for various tasks.

Another big plus is the strong community support that often accompanies open-source tools. Enthusiasts and professionals alike share their knowledge, offering tips, updates, and solutions to common problems, creating a collaborative environment that keeps the software evolving.

And let’s not forget the cost advantage. By skipping licensing fees, users can save money, and the software often supports repairs or upgrades using easily accessible parts. This combination of affordability and adaptability makes open-source DLP 3D printing software a smart choice for everyone, from hobbyists experimenting at home to professionals tackling complex projects.

How does DLP 3D printing software enhance efficiency and precision in custom fabrication projects?

DLP 3D printing software streamlines production by speeding up manufacturing processes, cutting down on material waste, and doing away with the need for conventional molds or tooling. The result? Shorter lead times and reduced costs for custom fabrication projects.

When it comes to precision, DLP software stands out with its high-resolution results, smooth surface finishes, and impressive dimensional accuracy. These features make it perfect for crafting intricate designs and highly detailed parts, delivering dependable and professional-quality outcomes even for the most complex tasks.