Top 7 CNC Monitoring Dashboards for Equipment Health

Unplanned downtime is expensive, but CNC monitoring dashboards can help machine shops avoid it. These tools track machine performance in real time, flagging issues early to improve maintenance and efficiency. They also support preventive maintenance, reduce unexpected breakdowns, and integrate with enterprise systems for smoother operations. Here are seven popular dashboards to consider:

- MachineMetrics: Cloud-based, broad CNC compatibility, real-time monitoring, predictive maintenance, and historical analytics.

- MERLIN Tempus: Modular design, real-time insights, downtime tracking, and customizable reports.

- Ignition with Innorobix MTConnect Module: Uses MTConnect for seamless multi-brand CNC integration and advanced reporting.

- Autobits: IoT-based, easy setup, supports major brands, and provides unified dashboards.

- FANUC MT-LINKi: Tailored for FANUC machines, real-time monitoring, and predictive maintenance.

- Siemens Analyze MyMachine / MindSphere: Exclusive to Siemens, combines edge and cloud analytics for in-depth insights.

- Heidenhain StateMonitor: Web-based, multi-brand compatibility, and maintenance planning tools.

Quick Comparison:

| Dashboard | CNC Compatibility | Real-Time Monitoring | Maintenance Features | Analytics & Reporting | Platform Type |

|---|---|---|---|---|---|

| MachineMetrics | Broad | Yes | Predictive | Historical & OEE | Cloud-based |

| MERLIN Tempus | Popular brands | Yes | Preventive | Customizable | Windows-based |

| Ignition with MTConnect | MTConnect-enabled | Yes | Automated workflows | Advanced templates | Web-based |

| Autobits | Major brands | Yes | Reminders | Unified dashboards | IoT-based |

| FANUC MT-LINKi | FANUC-specific | Yes | Predictive | Utilization reports | Integrated |

| Siemens Analyze | Siemens-only | Yes | Condition-based | Cloud analytics | Cloud & Edge |

| Heidenhain StateMonitor | Multi-brand | Yes | Condition-based | Trend analysis | Web-based |

Choose based on your shop's needs - whether it's compatibility, advanced analytics, or ease of use. These tools can help you cut costs, extend equipment life, and improve production.

MachineMetrics Production Monitoring and Analytics Platform [Demo 2023]

1. MachineMetrics Dashboard

MachineMetrics offers a straightforward way for U.S. manufacturers to turn raw machine data into practical insights. This cloud-based platform connects directly to CNC machines, giving manufacturers the tools to improve production efficiency and keep equipment running smoothly. Let’s break down how MachineMetrics brings real-time data to life.

Real-time Machine Data Visualization

The MachineMetrics dashboard presents machine data in a clean, easy-to-read format that shop floor managers can grasp at a glance. It uses widgets to display live updates on machine status, cycle times, and production counts. Operators can keep tabs on multiple machines on a single screen, with color-coded indicators that instantly show whether equipment is running, idle, or experiencing issues.

By tracking key metrics like spindle utilization, feed rates, and part counts, the system can alert operators the moment something goes off track. This immediate feedback helps teams address small problems before they turn into major disruptions.

Preventive and Predictive Maintenance Support

MachineMetrics goes beyond traditional maintenance schedules by using machine data to predict potential failures. It monitors factors like vibration levels, temperature changes, and power usage to catch early signs of trouble.

Instead of relying on fixed maintenance intervals, the system sends alerts based on actual machine usage. This approach avoids unnecessary maintenance while reducing the risk of unexpected breakdowns.

The platform also features a maintenance calendar that syncs with work schedules, making it easier to plan repairs during downtime. Maintenance records are automatically logged, creating a detailed history for each machine. Plus, the system’s compatibility with various controllers ensures flexibility across diverse setups.

Integration with Various CNC Brands/Controllers

MachineMetrics supports a wide range of CNC controllers without requiring expensive hardware upgrades. It works seamlessly with controllers from well-known brands like Fanuc, Haas, Mazak, Okuma, and Siemens using native protocols, often eliminating the need for additional sensors.

For older machines or less common controllers, the platform provides adaptable solutions like MTConnect adapters or custom integrations. It can gather data directly from machine PLCs or rely on external sensors when a direct connection isn’t possible.

Historical Analytics and Reporting Tools

To help manufacturers spot trends and boost efficiency, MachineMetrics stores years of production data. Its reporting tools deliver detailed insights into metrics like machine utilization rates, production efficiency, and quality performance over chosen time frames.

Managers can automate reports on key metrics, including downtime analysis, which pinpoints when and why machines stopped. This helps teams tackle recurring problems more effectively.

The platform’s analytics can also link production data to external factors like operator shifts, material quality, or environmental conditions. This added layer of insight helps manufacturers understand which variables have the greatest effect on production outcomes.

2. MERLIN Tempus by Memex

MERLIN Tempus is a platform designed to monitor and analyze manufacturing processes in real time. Its name, derived from the Latin word for "time", highlights its focus on helping U.S. manufacturers optimize equipment efficiency by closely tracking machine states and production times.

Real-time Machine Data Visualization

The platform's dashboard offers a clear, actionable overview of machine performance using a simple "red-light-green-light" system to indicate equipment status. Operators can easily monitor machine events such as overrides, program names, and alarms through dynamic "Metrics Widgets." This data is accessible on web-enabled devices, tablets, or smartphones, ensuring flexibility in monitoring. Additionally, an integrated event viewer provides a detailed log of machine operations, tracking both machine and operator performance over time.

Seamless Integration with CNC Brands and Controllers

MERLIN Tempus is built for seamless connectivity across the shop floor. It supports a range of software protocols, including MTConnect, Fanuc Focas, and OPC, enabling smooth integration with various CNC brands. Its modular design allows the platform to function independently of corporate networks while still offering a comprehensive enterprise-level view of productivity through a web browser.

Support for Preventive and Predictive Maintenance

The system also aids in maintenance planning by offering configurable email alerts, a Shift Scheduler, and an operator portal to classify downtime and part rejections. With the optional MERLIN Operator Portal, operators can log downtime and rejected parts directly from the shop floor, making it easier to identify and address issues promptly.

Historical Analytics and Reporting Tools

MERLIN Tempus goes beyond real-time monitoring by turning raw machine data into meaningful insights. Its customizable, web-enabled reports are designed for use across all levels of a manufacturing team. These tools help reduce downtime, improve throughput, and support data-driven decision-making. The platform is scalable, accommodating both single and multi-plant operations, and eliminates the need for custom integration work, making it a versatile choice for manufacturers looking to enhance productivity.

3. Ignition with Innorobix MTConnect Module

When paired with the Innorobix MTConnect Module, Ignition becomes a powerful tool for CNC monitoring. By utilizing the MTConnect standard - an open, royalty-free protocol based on XML and HTTP - it enables smooth communication with CNC machines. This makes it an appealing choice for shops aiming to standardize their monitoring systems across various equipment brands.

Integration with Various CNC Brands/Controllers

Rather than relying on native protocols, Innorobix uses MTConnect to standardize connections. The Innorobix MTConnect Module acts as a bridge for any MTConnect-compliant agent application, simplifying both configuration and data mapping.

This module is compatible with a wide range of major CNC brands, including Fanuc, Haas, Mazak, Okuma, Siemens, Heidenhain, DMG Mori Seiki, Makino, and Mitsubishi. Additionally, it supports other brands like Allen-Bradley CNC systems, Doosan, Fagor, and NUM controllers, making it a flexible solution for shop floors with mixed equipment.

In April 2025, Innorobix showcased this compatibility by providing detailed instructions for integrating a Mazak Integrex i-200S with Ignition using their MTConnect Module. This setup allowed real-time data - such as spindle speeds, feed loads, and tool positions - to flow directly into an Ignition MES system, enabling live status updates. This kind of integration sets the stage for efficient data visualization and monitoring, as explored below.

Real-time Machine Data Visualization

Ignition simplifies the process of converting machine outputs into a standardized MTConnect format, ensuring that data from various vendors can be visualized on a single platform. Through Ignition's customizable dashboards, operators can track vital metrics like spindle performance, feed rates, and tool positioning in real time.

The platform supports multiple data streams simultaneously, enabling manufacturers to monitor machines from different vendors through a unified interface. This eliminates the need for separate monitoring systems for each machine brand, reducing complexity and cutting down on training time for operators.

Historical Analytics and Reporting Tools

Beyond real-time monitoring, Ignition's historical data tools allow manufacturers to plan maintenance schedules and improve performance. The Tag Historian is at the core of this functionality, providing long-term data storage when integrated with the Innorobix MTConnect Module. This feature ensures extensive records are available for in-depth analysis over time.

With historical data, manufacturers can perform predictive maintenance, identify trends, and refine processes based on past performance. By comparing current data with historical patterns, teams can uncover opportunities for enhanced equipment efficiency and reliability.

Ignition also offers a Reporting Module that works seamlessly with the Tag Historian to deliver comprehensive reporting capabilities. Using a drag-and-drop interface, users can create dynamic PDF reports featuring charts, graphs, and tables. These reports pull data from various sources, including SQL databases, the Tag Historian, and alarm journal events. The system supports the creation of key manufacturing reports, such as production summaries, efficiency metrics, downtime tracking, and OEE (Overall Equipment Effectiveness) management.

4. Autobits CNC Machine Monitoring

Autobits CNC Machine Monitoring is an industrial IoT solution designed to gather and transmit real-time data from CNC machines across the shop floor. It uses IoT gateways that are easy to set up, featuring a plug-and-play design for automatic data collection without the need for complicated configurations. This approach ensures compatibility with a wide range of CNC machine brands.

Integration with Various CNC Brands/Controllers

One of Autobits' key strengths is its ability to work seamlessly with different CNC machines and controllers. With connectivity options like Wi‑Fi, Bluetooth, and Ethernet, it’s well-suited for environments that use a mix of machine brands.

The platform is especially effective with FANUC and Siemens controllers, offering unified monitoring even in setups with diverse controllers. Most data collection happens through Ethernet, and the system’s Smart Supervisor can be fully operational within 60 minutes of installation. Additionally, it allows customization to address specific manufacturing requirements.

Real-time Machine Data Visualization

Autobits takes compatibility a step further by offering a unified dashboard that consolidates data from machines with various controllers. This real-time visualization feature provides a clear and comprehensive view of machine performance and operational metrics on a single platform. The continuous data flow ensures up-to-the-minute updates on equipment health, allowing users to spot and address potential issues before they become major problems.

sbb-itb-b5aecec

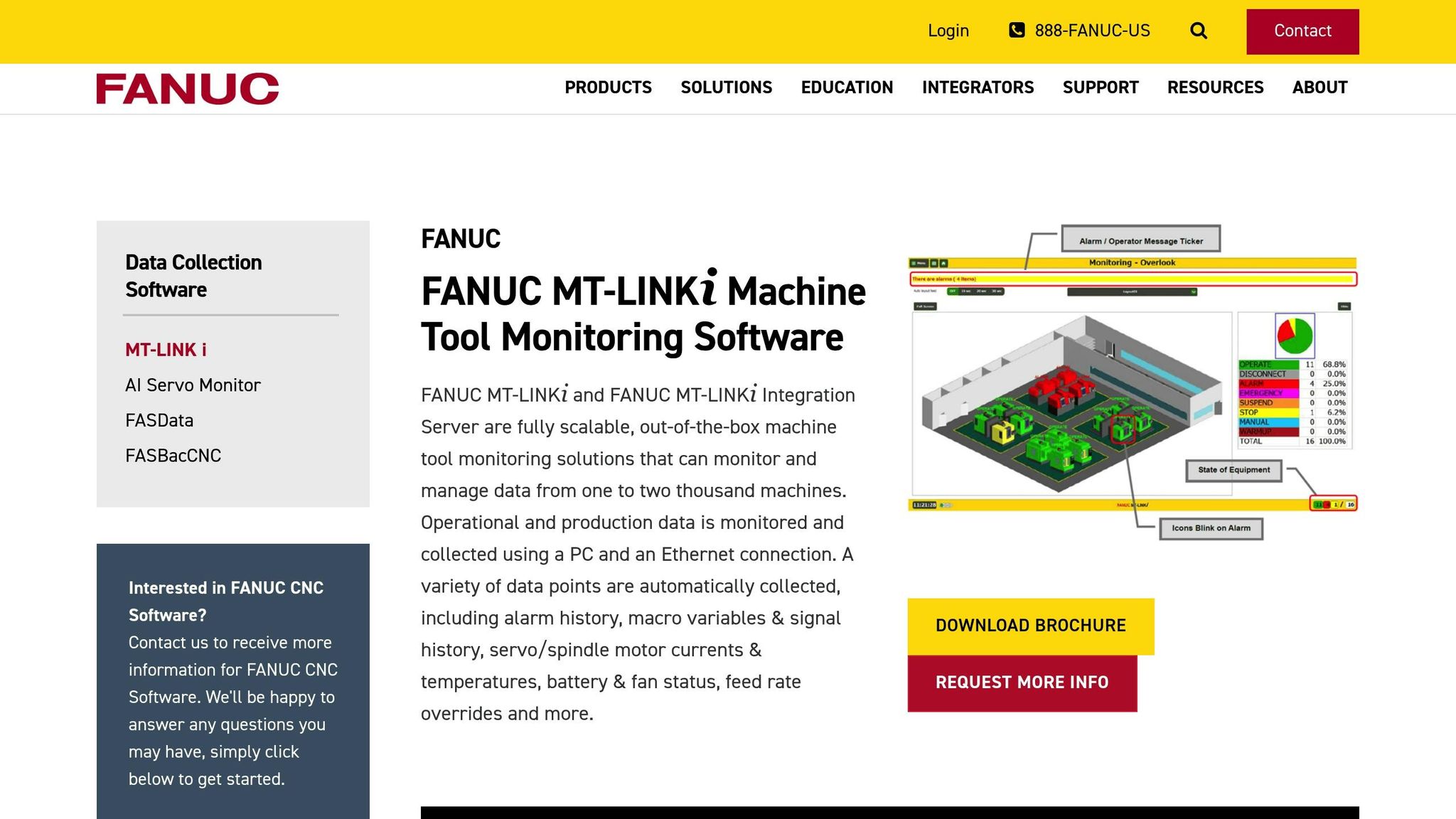

5. FANUC MT-LINKi Dashboard

FANUC's MT-LINKi Dashboard stands out as a native solution tailored specifically for FANUC machines. This cloud-based subscription service provides seamless real-time monitoring directly through FANUC controllers, offering an integrated experience that third-party dashboards can’t fully replicate.

Integration with FANUC Controllers

The MT-LINKi Dashboard connects effortlessly to FANUC machines using their built-in network capabilities. There’s no need for extra hardware or complicated setups. It supports modern controller series like the 30i, 31i, and 32i, giving users access to machine data that external systems simply can’t reach.

Real-time Machine Data Visualization

This dashboard delivers live updates on critical machine metrics such as spindle load, feed rates, program execution, and overall status. It also tracks part counts, cycle times, and utilization, refreshing every few seconds on an easy-to-use web interface. With color-coded indicators, users can quickly identify whether machines are running, idle, or facing issues. For those who need deeper insights, parameters like spindle speed and tool life are just a click away.

Preventive and Predictive Maintenance Support

MT-LINKi tracks vital stats like machine hours, cycle counts, and component usage to send timely maintenance alerts. By analyzing trends in tool life, spindle hours, and servo performance, it helps schedule repairs during planned downtime, reducing the risk of unexpected breakdowns.

Historical Analytics and Reporting Tools

The system also keeps detailed historical records, which can be used for trend analysis. Users can generate reports on metrics like machine utilization, efficiency, and downtime, broken down by machine, shift, or time period. These insights are invaluable for making informed decisions about production planning and equipment upgrades.

6. Siemens Analyze MyMachine / MindSphere

Siemens combines its Analyze MyMachine/Condition application with the MindSphere cloud platform, blending real-time data collection via Sinumerik Edge with long-term analytics in the cloud. This pairing delivers a thorough solution for CNC monitoring and performance evaluation.

Integration with Siemens CNC Systems

Siemens offers seamless compatibility between its CNC systems and the Analyze MyMachine /Condition application. Specifically designed for Sinumerik Edge, this system ensures smooth and efficient integration within Siemens' ecosystem. It works exclusively with Siemens devices, like the S7-1200 PLC Controllers, which users from the devicebase community have praised for their reliable compatibility. While this limits its use to Siemens products, it guarantees high-quality data collection from trusted equipment.

Real-time Machine Data Visualization

The SINUMERIK Edge application provides operators with an easy-to-use interface that presents machine data in both table and graph formats. Key metrics - such as axis stiffness, backlash, friction, signature, and quadrant errors - are displayed, creating a unique mechanical "fingerprint" for each machine. This detailed visualization allows operators to monitor critical performance indicators at a glance.

Preventive and Predictive Maintenance Support

By tracking these parameters, operators can spot early signs of wear or performance issues. This enables condition-based maintenance and scheduled repairs, helping to avoid unexpected downtime and costly disruptions.

Historical Analytics and Reporting Tools

The MindSphere platform enhances monitoring by offering long-term analytics and visual reports. Users can analyze data trends over time, compare performance across multiple machines, and identify patterns or anomalies. This cloud-based feature supports manufacturers in developing effective maintenance strategies and improving overall operational efficiency.

7. Heidenhain StateMonitor

Heidenhain StateMonitor is a web-based CNC monitoring tool designed to provide real-time performance insights, helping operators make quick, informed decisions on the shop floor.

Real-Time Monitoring

This dashboard offers a clear, live view of machine status, making it easy for operators to keep track of multiple machines at once. Its user-friendly interface is designed for efficiency and works seamlessly across different CNC systems.

Integration and Compatibility

One of the standout features of Heidenhain StateMonitor is its ability to integrate with a variety of CNC systems. This makes it especially useful for machine shops that operate with a mix of equipment. Its compatibility across multiple controllers ensures it fits well in environments with diverse CNC brands.

Maintenance and Analytics

StateMonitor goes beyond real-time tracking by utilizing historical data to enhance maintenance planning. It gathers and analyzes trends, helping teams implement condition-based maintenance strategies. This proactive approach not only optimizes workflows but also minimizes downtime, aligning with the broader goals of preventive maintenance and improved production efficiency.

Feature Comparison Table

Choosing the right CNC monitoring dashboard can feel overwhelming, but understanding the differences between platforms makes it easier to find the perfect match for your needs. Below is a handy table that breaks down the core features of some popular options, allowing for a quick side-by-side comparison.

| Dashboard | Supported CNC Brands/Controllers | Real-Time Monitoring | Overall Equipment Effectiveness & Analytics | Preventive/Predictive Maintenance | Usability |

|---|---|---|---|---|---|

| MachineMetrics | Broad compatibility with various machine types | Monitors machine status and tracks production | Offers OEE calculations and reporting | Provides maintenance alerts and predictive analytics | Cloud-based interface |

| MERLIN Tempus | Supports popular CNC brands | Tracks real-time production data and cycle performance | Delivers OEE metrics with trend analysis | Schedules maintenance based on equipment condition | Windows-based with customizable dashboards |

| Ignition with Innorobix | Compatible with MTConnect-enabled controllers | Provides live data visualization and alarm management | Includes OEE templates and historical reporting | Automates maintenance workflows | Web-based with drag-and-drop interface |

| Autobits | Supports several major CNC brands | Monitors machine status and job tracking | Calculates performance metrics | Offers maintenance reminders and downtime analysis | Simple web interface with mobile access |

| FANUC MT-LINKi | Specifically designed for FANUC controllers | Delivers real-time machine data monitoring | Provides efficiency and utilization reports | Focuses on predictive maintenance for FANUC systems | Integrated interface with tablet compatibility |

| Siemens Analyze MyMachine | Optimized for Siemens controllers | Tracks machine status and energy usage | Includes advanced analytics and benchmarking tools | Provides maintenance recommendations | Cloud-based with industrial IoT integration |

| Heidenhain StateMonitor | Broad compatibility across CNC brands | Offers real-time web-based status tracking | Provides performance trend analysis | Maintains historical data for maintenance planning | User-friendly, cross-platform interface |

Platforms like MachineMetrics and Heidenhain StateMonitor are great for mixed machine fleets, offering broad compatibility. On the other hand, brand-specific shops can benefit from specialized solutions like FANUC MT-LINKi or Siemens Analyze MyMachine, which are tailored for specific controllers.

Budget considerations vary by platform. Cloud-based options often operate on subscription models, while on-premises solutions may require a higher initial investment but have lower ongoing costs. Ease of use also differs: straightforward systems like Autobits and Heidenhain StateMonitor are ideal for smaller operations, while more customizable tools like Ignition with Innorobix may require additional training.

For shops looking to minimize downtime, dashboards with advanced analytics are invaluable. They help forecast potential issues, enabling predictive maintenance and reducing unexpected disruptions.

Conclusion

Real-time monitoring and predictive maintenance play a big role in keeping operations running smoothly. When selecting a CNC monitoring solution, focus on your specific goals. Are you aiming to cut downtime, improve efficiency, or enhance product quality? Use key metrics like Overall Equipment Effectiveness (OEE) and machine utilization to guide your decision. The right dashboard should align with a strategy that prioritizes preventive maintenance and relies on data to drive smarter choices.

If you're in the market for CNC machining partnerships, the Machine Shop Directory is a valuable resource. It connects you with over 200 highly-rated machine shops that specialize in precision CNC machining and custom fabrication.

FAQs

How do CNC monitoring dashboards help prevent equipment failures and minimize downtime?

CNC monitoring dashboards are essential for keeping equipment in top shape by analyzing real-time machine data around the clock. They can spot early indicators of wear, declining performance, or potential problems, giving maintenance teams the chance to step in before minor issues turn into major breakdowns.

With the ability to support proactive maintenance scheduling, these dashboards help manufacturers cut down on unexpected downtime, extend the life of their machinery, and streamline overall operations. The result? Smoother processes, lower costs, and smarter use of resources.

What should machine shops look for when selecting a CNC monitoring dashboard?

When choosing a CNC monitoring dashboard, machine shops need to focus on a few key factors. First, ensure it works seamlessly with your current equipment and software. Compatibility is crucial, but so is how easily the system integrates into your existing workflow. Look for a dashboard with a simple, user-friendly interface that doesn’t require extensive training and can grow alongside your shop’s needs.

It’s also important to assess your shop’s specific requirements. Do you need real-time data monitoring? Does your shop operate a variety of machines? And, of course, consider the budget. Opting for a solution that aligns with these needs can boost productivity and simplify operations without unnecessary headaches.

Can CNC monitoring dashboards work with enterprise systems, and how does this improve manufacturing operations?

Yes, CNC monitoring dashboards can work effortlessly with enterprise systems like ERP (Enterprise Resource Planning) and MES (Manufacturing Execution Systems). This connection provides real-time insights into production metrics, empowering teams to make quicker, informed decisions based on accurate data.

By automating processes like job scheduling, inventory tracking, and performance monitoring, these dashboards help minimize downtime and streamline workflows. They also improve communication across departments, ensuring operations run more smoothly and machinery operates at its best.