How JIT Training Improves CNC Machining Efficiency

Machine shops face growing challenges: a shortage of skilled labor, increasing demand for precision, and pressure to reduce waste. Traditional training methods take too long and don't meet the fast-paced needs of modern CNC machining. Just-In-Time (JIT) training offers a solution by delivering task-specific skills exactly when operators need them. This approach shortens training time, reduces inefficiencies, and helps shops meet production demands without sacrificing quality.

Key Takeaways:

- What is JIT Training? A method focused on teaching practical, task-specific skills in short, modular lessons delivered on-demand.

- Why It Matters: It addresses labor shortages, improves production efficiency, and reduces defects by focusing only on relevant skills.

- How It Works: Training happens directly on CNC equipment, often using real-time feedback, simulations, and AR tools to enhance learning.

- Benefits: Faster onboarding, better problem-solving, and improved workforce flexibility, all while maintaining high-quality production.

JIT training aligns workforce skills with production needs, helping machine shops stay efficient and competitive in a challenging industry.

Just-in-Time Manufacturing (JIT) | Lean Six Sigma Complete Course.

Common CNC Machining Operation Challenges

Machine shops often grapple with obstacles that can disrupt their ability to produce high-quality parts on schedule and within budget. These challenges typically revolve around labor shortages, inefficiencies in production, and unpredictable demand.

Skilled Labor Shortages and Onboarding Issues

A major hurdle for the CNC machining industry is the lack of skilled machinists. By 2030, it's projected that 2.1 million manufacturing jobs in the United States could remain unfilled. As seasoned machinists retire, many machines sit unused due to the absence of trained operators, creating a bottleneck in production. This underscores the pressing need for focused and timely training programs to bridge the skills gap.

Production Inefficiencies and Defects

Defects in machining processes are another common issue that can slow down operations. Problems like uneven surface finishes, burn marks from overheating, parts failing to meet dimensional tolerances, and chatter marks caused by tool vibrations are frequent culprits. These quality issues not only reduce productivity but also point to the need for revisiting traditional training methods to ensure operators can tackle these challenges effectively.

Adapting to Shifting Production Demands

The ever-changing nature of production demands adds another layer of complexity. Machine shops must frequently adapt to fluctuating order volumes and evolving design requirements. The shortage of skilled operators makes it harder to scale operations swiftly, which can lead to inefficiencies. To navigate these shifts, a more flexible approach to training is essential. The importance of such adaptive solutions leads directly into the discussion on JIT training strategies in the next section.

How JIT Training Addresses CNC Machining Problems

When it comes to tackling the challenges in CNC machining, Just-In-Time (JIT) training offers a fresh approach. Instead of relying on lengthy and often outdated training programs, JIT training provides targeted learning exactly when operators need it most. This method is shifting how machine shops approach skill development, workforce adaptability, and production quality.

Focused, Practical Skill Development

JIT training takes a hands-on approach by delivering immediate, task-specific learning. Forget long-winded theory sessions - this method breaks down CNC tasks into short, actionable modules that operators can quickly absorb.

For instance, if a machinist runs into a specific production issue, JIT training offers instant access to the right solution. This means they can troubleshoot problems on the spot instead of waiting for a formal training session or relying on trial and error.

The flexibility of JIT training is a game-changer. Operators can access learning modules during machine setup, between production runs, or when switching parts. This timely delivery of knowledge bridges the gap between classroom training and on-the-job application, ensuring that operators are equipped to handle real-world challenges. Beyond solving immediate problems, this approach also prepares workers for a variety of roles, boosting their overall competency.

Enhanced Workforce Flexibility

JIT training is also a solution for staffing challenges, helping machine shops build a versatile and cross-trained workforce. This adaptability allows shops to respond quickly to changing customer demands, whether it’s shifting part types, managing fluctuating order volumes, or handling rush jobs - all without sacrificing quality.

"Having a flexible and cross-trained workforce allows companies to adapt quickly to changes in production requirements. Employees should be equipped to handle multiple tasks and roles." - cncmachines.com

With its modular design, JIT training enables operators to pick up new skills quickly. Whether it’s mastering a new machining process, learning programming techniques, or improving quality control practices, operators can adapt to production needs in real time. This flexibility reduces downtime and ensures that staff are always aligned with current demands, cutting costs associated with idle machines or underutilized personnel.

Boosting Production Efficiency and Quality

By improving workforce adaptability, JIT training naturally enhances operational efficiency. It standardizes information, speeds up onboarding, and increases productivity, all while reducing product defects.

The immediate application of skills is another key advantage. Operators can put new techniques into practice while the training is still fresh, avoiding the knowledge decay that often occurs with delayed application. Regular updates on the latest CNC technologies ensure that staff stay up to speed without disrupting production. This is particularly important as machine shops increasingly adopt advanced CNC systems and Industry 4.0 technologies.

The result? A more agile operation where quality improvements happen in real time. Operators can adjust their techniques based on live feedback, leading to consistent part quality and less waste throughout the production process. This systematic approach not only boosts efficiency but also sets the stage for long-term success in a competitive industry.

Key Elements of Effective JIT Training Programs

Creating an effective Just-In-Time (JIT) training program for CNC machining involves focusing on specific components that address operational challenges and deliver practical, immediate results. The best programs share elements that make learning hands-on, relevant, and instantly applicable to daily tasks.

Simulations and Real-Time Feedback

Modern CNC training programs often use advanced simulation tools to provide a safe, cost-effective environment for learning. These simulations let operators practice complex procedures, test cutting parameters, adjust tooling setups, and refine programming - all without the risk of costly mistakes. For example, digital twins allow trainees to explore hundreds of scenarios in a single shift, dramatically shortening the learning curve. What might take months to master traditionally can often be achieved in days.

Real-time feedback is another cornerstone of effective training. Operators receive instant performance metrics during both simulated and live machining, covering areas like cycle times, surface finish, tool wear, and energy use. This immediate feedback helps operators quickly fine-tune their techniques, building muscle memory and decision-making skills far faster than older training methods.

Additionally, augmented reality (AR) displays are becoming a game-changer in JIT training. These systems overlay digital guides directly onto equipment, showing optimal tool paths, flagging potential issues, and offering step-by-step instructions for complex setups. This visual guidance bridges the gap between theory and practice, making it easier for operators to apply what they’ve learned.

Modular Training for Core Skills

JIT training programs excel by breaking down CNC machining skills into bite-sized modules that are easy to digest and apply. Instead of overwhelming operators with lengthy courses, these programs deliver focused lessons tailored to immediate production needs.

Most modules take just 15-30 minutes to complete, fitting seamlessly into busy production schedules. For instance, CAD/CAM programming modules teach operators how to create toolpaths, optimize cutting parameters, and troubleshoot programming errors, using the same software and part files they’ll encounter on the job. This ensures that training is both practical and directly relevant.

Machine-specific modules focus on the unique features of different CNC systems, such as Haas, Mazak, or DMG Mori machines. These lessons cover everything from basic operations to advanced capabilities like adaptive machining and in-process measurement. By tailoring training to specific equipment, shops can ensure operators are prepared for their exact production environment.

Quality control modules are another essential component. These teach operators how to use precision measuring tools, interpret inspection data, and apply statistical process control techniques. Mastering these skills helps maintain consistent part quality while reducing scrap and rework rates.

Alignment with Lean Manufacturing Principles

The most effective JIT training programs are built around lean manufacturing principles, ensuring that every minute of training directly enhances productivity and efficiency. By focusing on the 20% of skills that generate 80% of results, these programs eliminate unnecessary information and help operators master the essentials that drive daily performance.

Continuous improvement is embedded into the training process through regular feedback and performance tracking. Operators are encouraged to identify bottlenecks, suggest process enhancements, and share insights with their team. This collaborative approach fosters a culture where everyone contributes to ongoing efficiency gains.

Standardization is another key element. By teaching consistent procedures for tasks like tool changes, part setups, and quality checks, JIT training reduces variability and improves predictability in production. Operators not only learn how to complete tasks but also how to do them in the most efficient, repeatable way possible.

Finally, value stream mapping concepts are included to help operators see how their work fits into the larger production process. This systems-level understanding empowers workers to make better decisions about priorities and resource use, benefiting the entire operation rather than just their immediate tasks. These lean-aligned strategies ensure that every training session delivers measurable improvements on the shop floor.

sbb-itb-b5aecec

Measurable Benefits of JIT Training for Machine Shops

When it comes to improving operations in CNC machining, the numbers speak for themselves. Just-In-Time (JIT) training has been shown to directly enhance both production efficiency and workforce skills. By delivering training that’s immediate and targeted, machine shops can see clear, measurable improvements that strengthen their overall strategy.

Enhanced Production Performance

JIT training has a proven track record of boosting production metrics. For example, it helps reduce cycle times by teaching operators to optimize toolpaths, streamline setups, and handle materials more efficiently. Faster learning curves mean operators become productive sooner, which helps lower labor costs.

Additionally, operators trained in proper cutting parameters and machine settings produce less scrap, reduce rework, and shorten setup times. This leads to energy savings and greater operational efficiency. With a better-trained team, decisions about machine utilization become smarter and quicker - especially critical in setups with frequent changeovers or smaller batch runs. These improvements build a more adaptable and efficient workforce, ready to meet shifting demands.

Strengthened Workforce Skills and Adaptability

JIT training doesn’t just improve production numbers - it also transforms the workforce. By offering hands-on, focused training modules, machine shops encourage cross-training, enabling operators to handle various machine types and tackle a range of part geometries. This flexibility is key to reducing bottlenecks and maintaining smooth workflows.

Operators also gain practical problem-solving and programming skills. They learn to identify and address common issues like tool wear or surface defects, making real-time adjustments without waiting for supervisor input. This reduces downtime and keeps production moving.

Perhaps most importantly, JIT training prepares machine shops to adapt quickly. A skilled and flexible workforce can scale operations to meet increased demand, whether it’s for a new contract or a busy production period. This readiness allows manufacturers to take on more complex, higher-value projects with confidence, ensuring they stay competitive in a fast-paced industry.

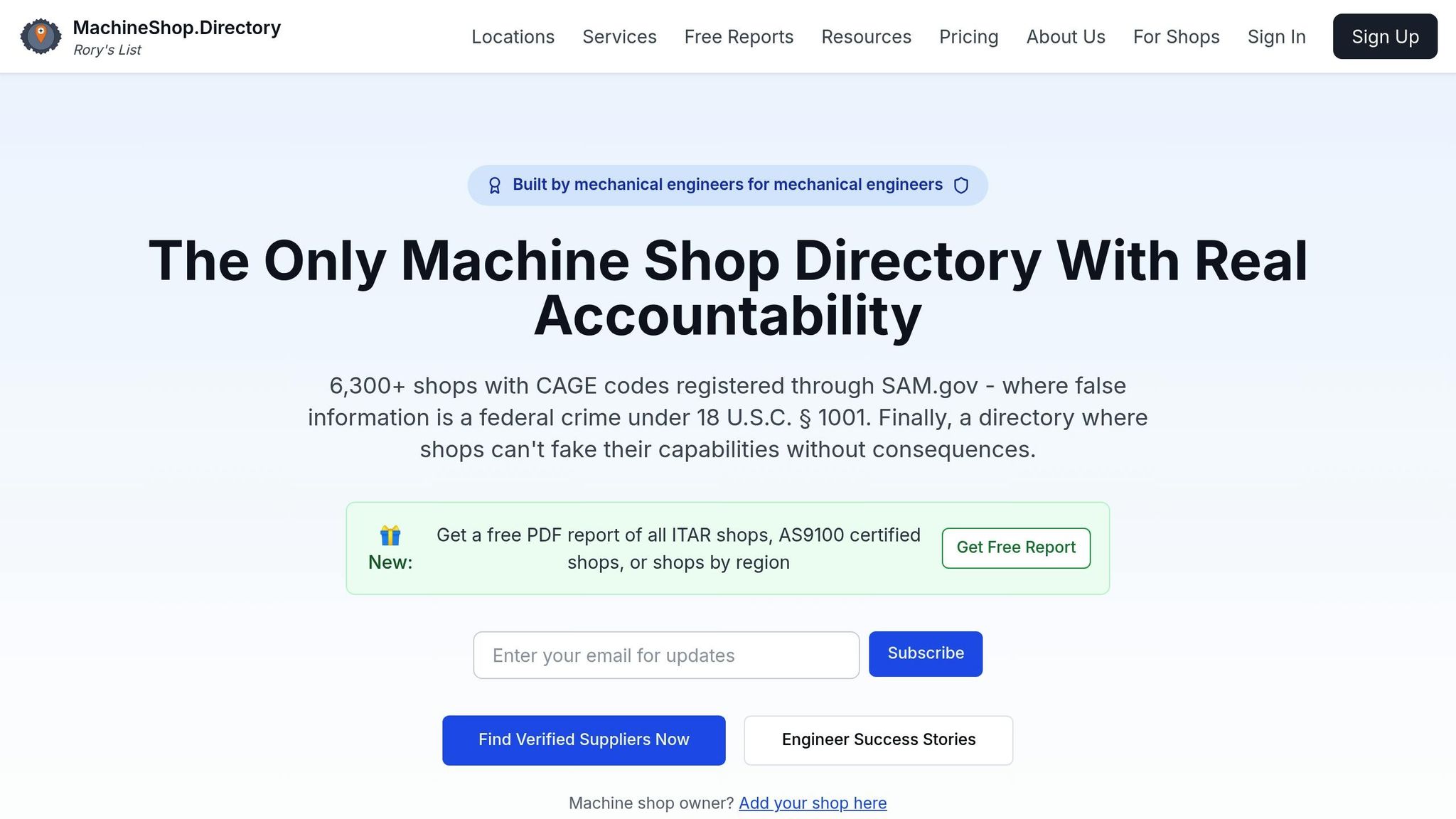

Using Machine Shop Directory for JIT Training Resources

To make Just-In-Time (JIT) training work effectively, you need partners who are experts in both CNC machining and workforce development. That’s where the Machine Shop Directory steps in. With over 200 top-rated machine shops specializing in precision CNC machining and custom fabrication, this resource simplifies the process of finding the right collaborators for modern CNC operations.

Connecting with Industry Leaders

The Machine Shop Directory is a go-to resource for machine shops looking to partner with experts in lean manufacturing and workforce development. Thanks to its Sort & Filter feature, users can quickly locate suppliers with the exact expertise they need. Each listing includes detailed company profiles and multimedia tools, allowing businesses to highlight their specialization in lean manufacturing. This makes it easier for machine shops to identify partners who can effectively support JIT training programs.

Simplifying Workforce Development

Finding the right partner for workforce development is easier with the directory’s well-organized listings. Each entry summarizes what the provider offers, enabling machine shops to compare specialties and directly connect with top industry players. This ensures that chosen partners not only understand JIT training principles but also bring practical experience with CNC machining processes and equipment. The result? Training programs that are immediately relevant and can be seamlessly integrated into daily operations. By linking machine shops with experienced leaders, the directory accelerates the implementation of effective JIT training strategies.

Conclusion: Improving CNC Machining Efficiency with JIT Training

Just-In-Time (JIT) training provides a practical solution for machine shops navigating the challenges of modern manufacturing. By delivering focused, hands-on learning exactly when it’s needed, JIT training minimizes the delays and inefficiencies tied to traditional, drawn-out onboarding processes, while creating a workforce that’s better equipped to adapt to change.

Shops that implement JIT training often see better production outcomes, less waste, and tighter quality control. This method ensures teams gain the skills they need at the moment they’re most relevant, helping to address issues like labor shortages and production slowdowns.

The success of JIT training hinges on collaboration with specialists in lean manufacturing and CNC machining. Incorporating real-time feedback and breaking skills into manageable modules fosters an ongoing cycle of improvement, driving performance gains across the board.

Machine shops ready to adopt JIT training can connect with over 200 highly-rated experts in precision CNC machining and custom fabrication through the Machine Shop Directory. This resource can help fast-track training initiatives and deliver measurable efficiency improvements.

As manufacturing continues to evolve, JIT training isn’t just an option - it’s a strategic step forward. The real question is: how soon can your shop take advantage of this approach?

FAQs

How does JIT training help address skilled labor shortages in CNC machining?

JIT (Just-In-Time) Training in CNC Machining

JIT training addresses the skilled labor shortage in CNC machining by providing workers with the precise skills they need, exactly when they need them. This method helps cut down on downtime, ensures employees are ready to meet operational demands, and lessens the dependency on a large workforce of highly skilled operators.

By incorporating automation, real-time machine data, and robotics into the process, JIT training allows facilities to maintain high productivity levels even with fewer experienced workers. These tools not only make better use of machinery but also promote ongoing skill development, helping businesses remain efficient and competitive in the face of labor shortages.

How do simulations and augmented reality (AR) tools improve JIT training for CNC operators?

Simulations and augmented reality (AR) tools are transforming the way CNC operators receive just-in-time (JIT) training. By offering realistic, hands-on experiences in a controlled environment, these technologies allow operators to practice complex tasks without the risks associated with live operations. This not only builds confidence but also helps reduce mistakes when transitioning to real-world tasks.

AR tools go a step further by simplifying setup processes and offering real-time guidance during operations. This reduces downtime and keeps workflows running smoothly. The interactive and engaging nature of these tools also speeds up the learning process, enabling operators to adapt to new systems more quickly. The result? Improved productivity and better overall performance on the shop floor.

How can machine shops use JIT training to enhance lean manufacturing and boost efficiency?

Machine shops can incorporate just-in-time (JIT) training into their lean manufacturing strategies by tailoring skill development to immediate operational needs. This method ensures employees gain the specific knowledge they require exactly when they need it, enabling them to handle production demands efficiently.

By focusing on key principles such as reducing inventory, cutting waste, and streamlining workflows, JIT training reinforces lean practices in everyday tasks. The outcome? Smoother production processes, better machine usage, and less downtime - all of which contribute to greater efficiency and quicker responses to customer needs.